Supported by an elite R&D team and advanced laboratory facilities, we provide reliable product development, testing, and technological innovation capabilities

The company has established an elite R&D team of 51 members, accounting for 17% of total employees, and has co-founded a university-enterprise R&D technology center with Wuhan University of Technology, forming a deeply integrated innovation ecosystem.

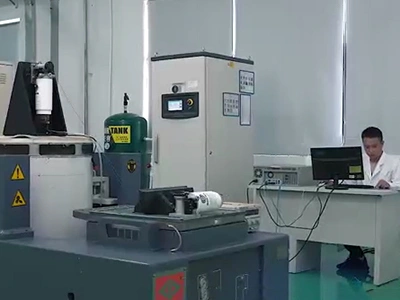

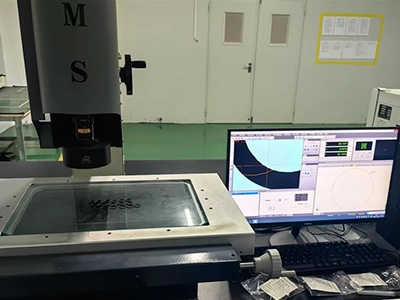

Supporting research efforts, the company has built a dedicated R&D base, including laboratory buildings, a technology center, a pilot workshop, and supporting facilities, creating an innovation pilot base for new product development and technology transfer. Saiensi has a 1,900-square-meter testing laboratory, equipped with multiple high-precision instruments such as coordinate measuring machines, universal tool microscopes, infrared carbon-sulfur analyzers, and atomic absorption spectrophotometers, as well as environmental testing chambers, oil pump testing equipment, and other specialized testing devices. Saiensi also operates a physical and chemical analysis lab, impact testing platforms, multifunction test benches, environmental test chambers, and static test benches. This extensive R&D and testing capability ensures reliable product quality.

Saiensi consistently pursues technological innovation, establishing a comprehensive system that combines independent R&D with collaborative industry-academia research. Long-term partnerships with Wuhan University of Technology, Hubei University of Arts and Science, and Hubei University of Automotive Technology provide strong technical and talent support.

Saiensi has independently developed the integrated electronic fuel pump with complete technical ownership and intellectual property rights, effectively solving the low-temperature starting challenges faced by diesel engines and diesel-powered vehicles. Related technologies have been granted 5 invention patents and 32 utility model patents, including brushless motor pumps, automatic oil pump fuel filter assemblies, and engine oil preheating devices.

The integrated electronic fuel pump received the 2019 China Science and Technology Innovation Award, achieving a critical technological breakthrough and filling a domestic gap. Saiensi also developed the first domestic brushless motor and control technology for fuel pumps, producing the PHF16 series brushless integrated electronic fuel pump. Compared to similar products, its failure rate is reduced by over 40%, service life increased by 50%, and product quality meets or exceeds international standards.

The Saiensi laboratory, established in 2017, includes:

Equipped for testing electric oil pumps, automotive component performance, and durability, the lab uses equipment from leading brands such as Yuanfang Optoelectronics, Dongling Vibration, and Jufu Instruments.

Let’s discuss how we can support your next project.