Compression gas springs from Saiensi deliver stable support and damping performance across automotive, machinery, furniture, and industrial automation applications. Designed for versatility and precision, these products can be fully customized to meet specific requirements in load capacity, stroke length, and installation configuration, ensuring reliable operation under diverse working conditions.

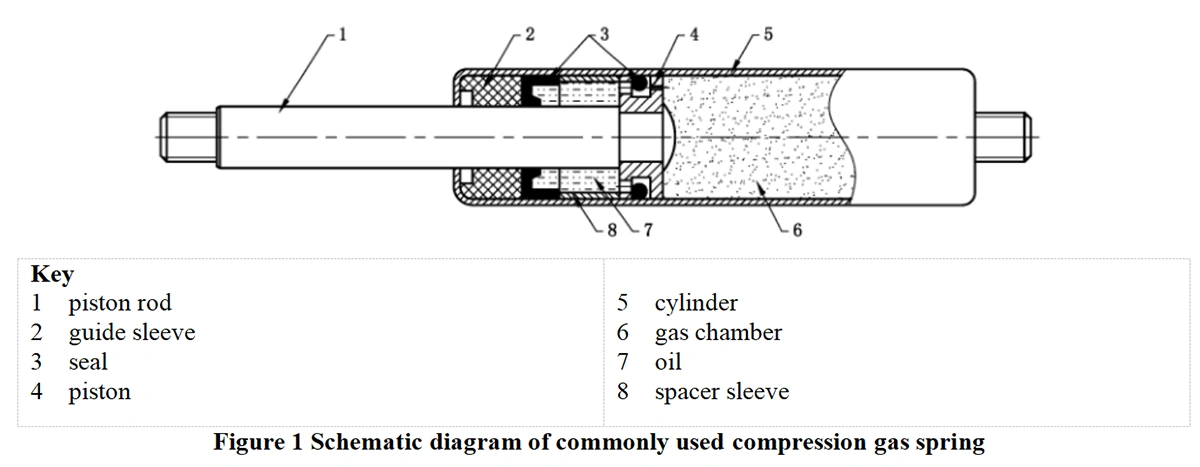

A compression gas spring consists of a cylinder, piston rod, sealing and guide package, and mounting joints.

In operation, the sealed pressure cylinder is filled with inert gas or an oil-gas mixture, maintaining the chamber in a high-pressure state. The pressure difference between the two sides of the piston, caused by their different cross-sectional areas, drives the piston rod to extend freely, providing smooth support or damping motion.

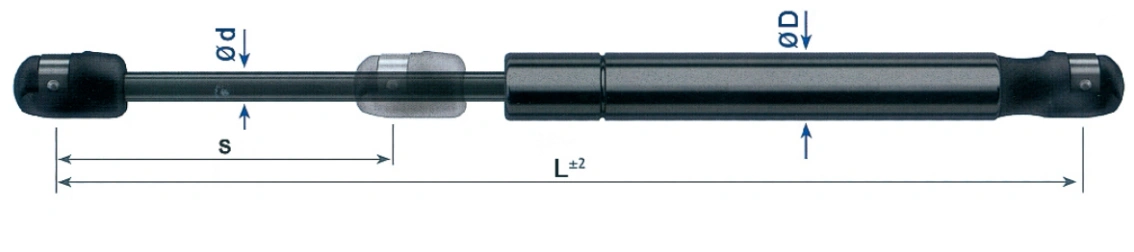

| d(mm) | D(mm) | S(mm) | L(mm) | Force F1(N) |

| 4 | 12 | 20-200 | 115-465 | 5-150 |

| 6 | 15 | 20-200 | 115-465 | 50-400 |

| 8 | 18 | 50-350 | 190-775 | 100-700 |

| 10 | 22 | 40-500 | 170-1090 | 100-1200 |

| 12 | 27 | 100-500 | 270-1120 | 500-1500 |

| 14 | 27 | 100-500 | 270-1120 | 500-2500 |

Single-leaf hinge bracket XW-1052

Single-leaf hinge bracket XW-1052

Hinged L-bracket XW-1053

Hinged L-bracket XW-1053

Bent two-hole mounting bracket XW-1054

Bent two-hole mounting bracket XW-1054

Deck hinge mount XW-1055

Deck hinge mount XW-1055

Long-slot deck hinge mount XW-1056

Long-slot deck hinge mount XW-1056

Short-slot deck hinge mount XW-1057

Short-slot deck hinge mount XW-1057

Triangular ball stud bracket XW-1061

Triangular ball stud bracket XW-1061

Flat ball joint bracket XW-1062

Flat ball joint bracket XW-1062

L-shaped ball stud bracket XW-1063

L-shaped ball stud bracket XW-1063

Double-wing ball stud bracket XW-1064

Double-wing ball stud bracket XW-1064

Plastic ball joint connector XW-1065

Plastic ball joint connector XW-1065

Plastic ball socket XW-1066

Plastic ball socket XW-1066

Metal ball socket XW-1067

Metal ball socket XW-1067

Eyelet end fitting XW-1068

Eyelet end fitting XW-1068

Gas spring mounting pin XW-1069

Gas spring mounting pin XW-1069

Dual-slot ball stud mounting bracket XW-1004

Dual-slot ball stud mounting bracket XW-1004

Rectangular ball stud mounting bracket XW-1005

Rectangular ball stud mounting bracket XW-1005

Single-slot ball stud mounting bracket XW-1006

Single-slot ball stud mounting bracket XW-1006

Square ball stud mounting bracket XW-1007

Square ball stud mounting bracket XW-1007

Triangular ball stud mounting bracket (short) XW-1008

Triangular ball stud mounting bracket (short) XW-1008

Triangular ball stud mounting bracket (medium) XW-1009

Triangular ball stud mounting bracket (medium) XW-1009

Triangular ball stud mounting bracket (long) XW-1010

Triangular ball stud mounting bracket (long) XW-1010

Triangular ball stud mounting bracket (black finish) XW-1011

Triangular ball stud mounting bracket (black finish) XW-1011

Offset triangular ball stud bracket XW-1012

Offset triangular ball stud bracket XW-1012

High-post round ball stud bracket XW-1013

High-post round ball stud bracket XW-1013

Circular ball stud bracket (small diameter) XW-1014

Circular ball stud bracket (small diameter) XW-1014

Three-hole ball stud bracket XW-1015

Three-hole ball stud bracket XW-1015

Circular ball stud bracket XW-1016

Circular ball stud bracket XW-1016

Circular compact ball stud bracket XW-1017

Circular compact ball stud bracket XW-1017

Circular ball stud bracket (black finish) XW-1018

Circular ball stud bracket (black finish) XW-1018

Low-post round ball stud mount XW-1019

Low-post round ball stud mount XW-1019

Clevis bracket with two-hole base plate XW-1040

Clevis bracket with two-hole base plate XW-1040

Double-lug clevis bracket with extended two-hole base plate XW-1041

Double-lug clevis bracket with extended two-hole base plate XW-1041

Double-lug clevis bracket with slotted base plate XW-1042

Double-lug clevis bracket with slotted base plate XW-1042

Reinforced clevis bracket with two-hole base plate XW-1043

Reinforced clevis bracket with two-hole base plate XW-1043

Vertical clevis bracket XW-1044

Vertical clevis bracket XW-1044

Reinforced clevis bracket XW-1045

Reinforced clevis bracket XW-1045

Clevis bracket with single-hole base plate XW-1046

Clevis bracket with single-hole base plate XW-1046

Need help choosing the right product or planning your project? We’re here to provide the assistance you need.