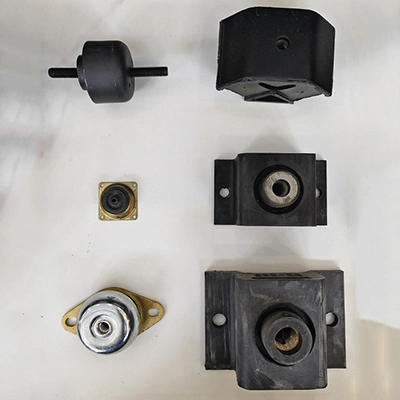

Rubber Anti-Vibration Mounts

Rubber Anti-Vibration Mounts

Anti-Vibration Mounts for Generators

Anti-Vibration Mounts for Generators

Two-Piece Vibration Isolators

Two-Piece Vibration Isolators

Cylindrical Vibration Isolators /Levelling Feet

Cylindrical Vibration Isolators /Levelling Feet

Saiensi specializes in the research, development, and manufacturing of rubber vibration isolators and mounts. With proprietary high-performance rubber formulations and advanced rubber-metal composite vulcanization processes, the company offers customized elastic modulus, damping coefficient, and stiffness designs to meet diverse operational requirements. The main product types include anti-vibration mounts, anti-vibration mounts for generators, two-piece vibration isolators, cylindrical vibration isolators made from materials such as natural rubber (NR) and nitrile rubber (NBR), with an operating temperature range of -40°C to 200°C. These products are widely applied in industrial equipment, automotive chassis, precision instruments, and construction, effectively extending equipment lifespan and enhancing operational stability.

| Material | Features | Advantages | Applications |

| Natural Rubber (NR) | Elastic modulus 1.5–2.5MPa, Temperature range -40°C~70°C, Loss factor tanδ 0.15–0.25 | High elasticity, strong fatigue resistance, Compression set ≤25% | Vibration mounts, suspension bushings, precision instrument isolation |

| Nitrile Rubber (NBR) | Hardness 40–90 Shore A, Temperature -20°C~100°C, oil resistance | 30% improved wear resistance, strong dynamic load adaptability | Fuel equipment vibration damping, hydraulic system seals |

| EPDM (EPDM) | Temperature -50°C~150°C, ozone/weather resistance, tanδ peak 0.08–0.12 | Anti-aging retention > 85%, stable across wide temperature range | Rail transit switch pads, outdoor construction supports |

| Butyl Rubber (IIR) | tanδ>0.4 (-30~80°C), airtightness, Temperature -35°C~130°C | Optimal damping, fatigue life >5 million cycles | High-speed rail vibration pads, body sealing elements |

| Chloroprene Rubber (CR) | Flame retardant, Temperature -30°C~130°C, Acid/alkali resistance | Ozone aging resistance, adjustable dynamic stiffness | Marine engine mounts, fire-fighting equipment |

| Polyurethane (PU) | Hardness 60A–75D, Temperature -40°C~120°C, 50% improved wear resistance | High load capacity (>3000kg), high-frequency vibration suppression | Heavy machinery bases, stamping machine isolation |

| Hydrogenated Nitrile (HNBR) | Temperature -40°C~180°C, oil resistance, High tear strength | Extreme environment adaptability, low permanent compression set | Engine mounts, high-temperature pump/valve damping |

Control arm bushings

Control arm bushings

Leaf spring bushings

Leaf spring bushings

Need help choosing the right product or planning your project? We’re here to provide the assistance you need.

Rubber vibration isolators use the elastic properties of rubber to reduce mechanical vibration, shock, and noise. They absorb and reflect vibration energy, preventing the propagation of vibration waves, thereby achieving damping, noise reduction, and minimizing impact-related damage.