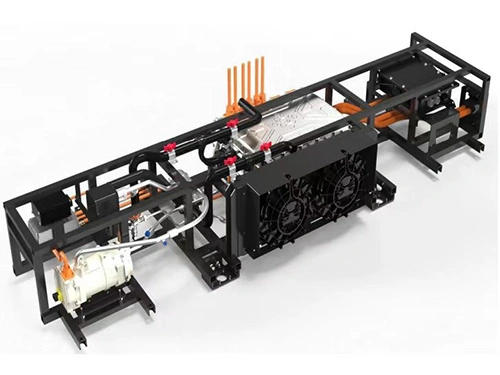

Battery Thermal Management System (BTMS)

Thermal management systems for electric vehicle (EV) and hybrid battery packs

Saiensi specializes in the production of vehicle thermal safety management systems, supported by a CNAS-certified laboratory and an 80% in-house manufacturing rate. We maintain strict control over materials, cost management, delivery, and quality.

Saiensi’s battery thermal management system (BTMS) ensures that vehicle batteries operate within the optimal temperature range during charging and discharging, enabling safe, efficient, and long service life performance.

Key Features of Thermal Management Technology

- High-temperature rapid cooling: Effectively dissipates heat when the lithium battery temperature rises, preventing or delaying thermal propagation that could cause fire or explosion during charging, and reducing the risk of thermal runaway.

- Low-temperature rapid heating: Preheats the battery under low-temperature conditions to ensure safe and efficient charging and discharging in cold climates, eliminating winter driving range anxiety for new energy vehicles.

- Forced circulation cooling: Minimizes internal temperature differences within the battery pack, preventing localized overheating and uneven aging, thereby extending overall battery life.

- Automatic control: Integrates real-time battery monitoring and intelligent control. The system automatically switches between shutdown, cooling, heating, and self-circulation modes based on operational data and battery status.

- All-climate operation: Designed to perform reliably across diverse climates and driving conditions of new energy vehicles.

- High compatibility: Supports online programming, firmware updates, and remote diagnostics.

Product Series

New Energy Thermal Management Controller System

Interface Resources

- 6 × PWM: Circulation pump, condenser fan, MEMS sensor, electronic expansion valve

- 10 × AI: Inlet/outlet temperature, ambient temperature, evaporator temperature, condenser temperature, liquid level, high/low-pressure sensors, valve 1 & valve 2 feedback

- 4 × DO: Valve 1, valve 2, main power relay, auxiliary relay

- 4 × CAP: Pump fault feedback, fan fault feedback

- 3 × CAN: Compressor, water heating PTC, BMS system communication

- Expandable to 35 PIN design upon request.

Dual-Cycle Thermal Management System (Battery + Main Drive Motor Control)

- Operating temperature: –15°C to +60°C

- Coolant: Ethylene glycol + water (1:1)

- Communication protocol: CAN 2.0

- Voltage:

- High voltage: DC 260–450V / 400–750V

- Low voltage: DC 9–16V / 18–32V

- Cooling capacity: 1kW / 3kW / 5kW

- Heating capacity: > 5kW (external series heating or per specification)

- Cooling for drive system: 50–80kW

- Applications: New energy utility vehicles, airport shuttles, tractors, unmanned charging units

- Mounting dimensions: Customizable.

Dual-Cycle Thermal Management System (Battery + Drive Motor Control, Heavy-Duty Version)

- Operating temperature: –15°C to +60°C

- Coolant: Ethylene glycol + water (1:1)

- Voltage:

- High voltage: DC 260–450V / 400–800V

- Low voltage: DC 9–16V / 18–32V

- Cooling capacity: 5kW / 8kW

- Drive system cooling: 100–150kW

- Winter H\heating: Utilizes waste heat from the drive system for battery warming.

- Applications: Electric heavy trucks, electric buses

- Mounting dimensions: Customizable.

Integrated Vehicle Thermal Management System (Battery + Cabin HVAC + Electronic Control)

- Operating temperature: –15°C to +60°C

- Coolant: Ethylene glycol + water (1:1)

- Voltage:

- High voltage: DC 260–450V / 400–800V

- Low voltage: DC 9–16V / 18–32V

- Cooling capacity: 5kW / 8kW / 10kW

- Drive system cooling: 150–200kW

- Winter heating: Supports waste-heat circulation from the drive system to the battery.

- Applications: New energy heavy trucks

- Features: Developed jointly with vehicle chassis manufacturers, offering system calibration, custom compressors, and integrated control modules. Can be expanded to heat pump-based thermal management systems.

Vertical modular unit

Request a Quote

Standalone Battery Thermal Management System

- Operating temperature: –15°C to +60°C

- Coolant: Ethylene glycol + water (1:1)

- Voltage:

- High voltage: DC 260–450V / 400–800V

- Low voltage: DC 9–16V / 18–32V

- Cooling capacity options: 3kW / 5kW / 7.5kW / 10kW / 12kW

- Heating capacity: > 5kW (external series heating or per specification)

- Applications: Electric buses, battery-swap heavy trucks, mining vehicles, rail locomotives, electric loaders, excavators, port AGVs

- Mounting dimensions: Customizable.

Product Overview

| Model | Cooling Capacity (kW) | Heating Capacity (kW) | Dimensions (mm) | Vehicle Type | Application |

| BTMS-L3R0F0-V | 1.5/3,5 | 0 | L620-W500-H430 | EV | Forklifts, battery-swap loaders |

| BTMS-L6R0F0-H | 6/8/10 | 5.6.8.10 | L835-W600-H305 | EV | Heavy trucks, excavators, loaders |

| BTMS-L7R0F0-H | 7.5/10 | 5.6.8.10 | L835-W600-H295 | EV | Tractors, trains, bulldozers |

| BTMS-L8R0F0-V | 8/10/12 | 5.6.8.10.14 | L620-W500-H430 | EV | Heavy trucks, construction vehicles |

Detailed specifications are available upon request or can be tailored according to the actual needs of new energy vehicle models.